The application range of plastic injection-molded products is now very broad, with various plastic items visible everywhere. These products play an important role in our daily lives, leading to an increasing number of companies specializing in injection-molded plastic parts processing. Due to differences in technical capabilities and equipment levels among companies, the quality of plastic products varies significantly in brand and type.

1. Visual Identification

In the actual machining of molds, visual inspection is a key indicator of product quality. High-quality plastic products generally have a clear, colorless appearance, with high transparency and no impurities on the surface. For example, products like plastic storage bags and containers should have high transparency and be free from visible impurities. If these items have low transparency or contain many impurities, it indicates lower quality. When selecting raw materials, mold machining typically prioritizes superior processing materials. Opaque products often use inferior materials, potentially recycled. Thus, through visual inspection, one can effectively judge the quality of machined molds.

2. Smell Identification

A good machined mold should have a mild scent with a faint plastic smell, which typically indicates better product quality. If a plastic product emits a strong, pungent odor, it may suggest quality issues and a lack of effective quality assurance.

3. Touch Identification

Touch is also an important way to assess the quality of machined molds. By feeling the product’s edges, one can judge its processing quality. Smooth, non-abrasive edges indicate a high-quality product, suitable for premium industries. In contrast, products with rough or visibly flawed edges may be of inferior quality.

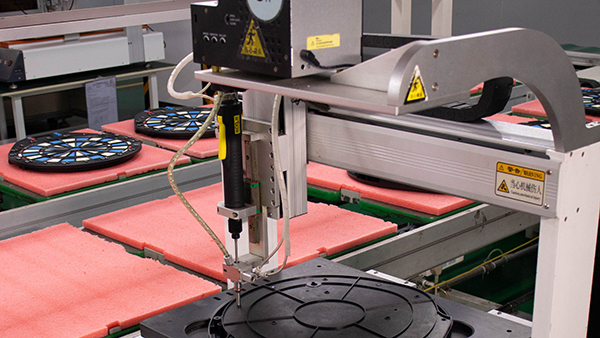

DAYIN Plastic Products Co., Ltd. specializes in home appliance mold manufacturing and provides OEM/ODM contract manufacturing services. As a comprehensive manufacturing solution provider integrating R&D and production, our products include robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D staff, and more than 100 injection molding machines, we are committed to delivering high-quality manufacturing services and creating greater value for our clients.